PCAP in automotive applications? Yes, we can!

Capacitive sensors are great – highly reliable and have a wide range of functions. You can’t argue with their usefulness in household electronics, especially as panels in such products are becoming thinner and lighter with almost every iteration. In the automotive world, however, this isn’t exactly desirable. In this industry, sensitive sensor technology is subject to stricter requirements, both in terms of service life and environmental influences. For example, display and touch systems in automotive applications must be much more robust in several important ways:

Capacitive sensors are great – highly reliable and have a wide range of functions. You can’t argue with their usefulness in household electronics, especially as panels in such products are becoming thinner and lighter with almost every iteration. In the automotive world, however, this isn’t exactly desirable. In this industry, sensitive sensor technology is subject to stricter requirements, both in terms of service life and environmental influences. For example, display and touch systems in automotive applications must be much more robust in several important ways:

- They need to be able to cope with a temperature range of -30° to 85°

- They must have an exceptionally high standard of readability, even with sunglasses

- Be able to withstand high vibrations

- Meet high standards of electromagnetic compatibility (EMC) and Electromagnetic interference (EMI)

Where EMC requirements are concerned, ghost touches must stay within an irradiation of 150V/m. With our new touch controller this is no longer a big challenge, However, the ability to limit all radiation remains significant, especially at lower frequencies. In automotive applications, radiation is measured at lower frequencies than in industrial projects and this is a big problem for PCAP, as the working frequency of the touch is exactly in this frequency range. To meet these challenges, we have designed a highly robust touch solution that passes all necessary EMI/EMC tests in the automotive field. We have adapted the hardware design, focusing on the FPC of the touch and created a new firmware in the touch IC, based on the SIS 95xx family. This includes new security mechanisms, which allow the host to check if the touch IC is still working, as well as communication, touch functionality, FPC functionality and data consistency without waking it from sleep mode. Our special Touch with 2 FPC, (also based on SIS 95xx) even allows for checking the consistency of the touch coordinates against Ghost Touches. We talk about this in more detail in a recent article.

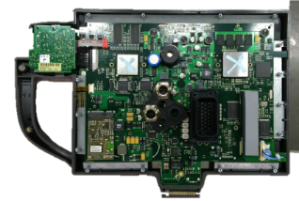

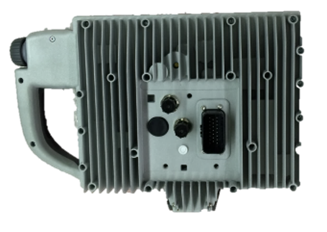

In this picture, we have an example of a fully installed HMI device – a guidance system for agricultural machinery. As you might imagine, a touch solution in such an environment will encounter multiple variables in temperature, light, interference and movement and ours successfully negotiates all of these – often simultaneously – quite literally out in the field.

Do you have an automotive application challenge that requires our expertise? We are on hand to guide you in the creation of display or touch solutions that meet your requirements. Find out how Avnet Embedded can propel your product innovation and get in touch today.