Where displays are concerned, plenty of acronyms fly around. MIPI is one, LVDS and RGB/TTL are some others. You’d expect all three to be completely different, but life is never that precise, is it? For example, MIPI displays also use LVDS standards and as puzzling as that might sound, there are actually some fairly sound reasons for it.

These days, very few displays use a parallel communication, and even then, it’s usually only for smaller screen sizes. For such RGB/TTL displays, the color information of every individual pixel is usually communicated over a parallel bus of 8 bits per color. This results in a 24-line width of the bus and, of course, this will also require a physically large connection cable. The TTL display uses higher voltage levels, compared to LVDS or MIPI displays. The communication is not as stable to external noise. Power consumption for TTL communication is higher, and the communication speed is slower.

All pretty good reasons to invent a better interface.

LVDS is a broad technical specification for signaling and uses differential signals of low voltage to send data. This can be seen in the connection cables used for LVDS signaling, where each wire is assigned to a different signal and the group is twisted to reduce the impact of surrounding electrical noise which would disturb the signal. You may see multiple twisted pairs within the display connection cable when it follows the LVDS specification.

Of course, we also see these twisted wires in a regular Ethernet cable, the type that typically connects a modem and a PC, but it doesn’t follow the LVDS specification. So, be mindful that twisted wires aren’t the automatic indicator of a display cable.

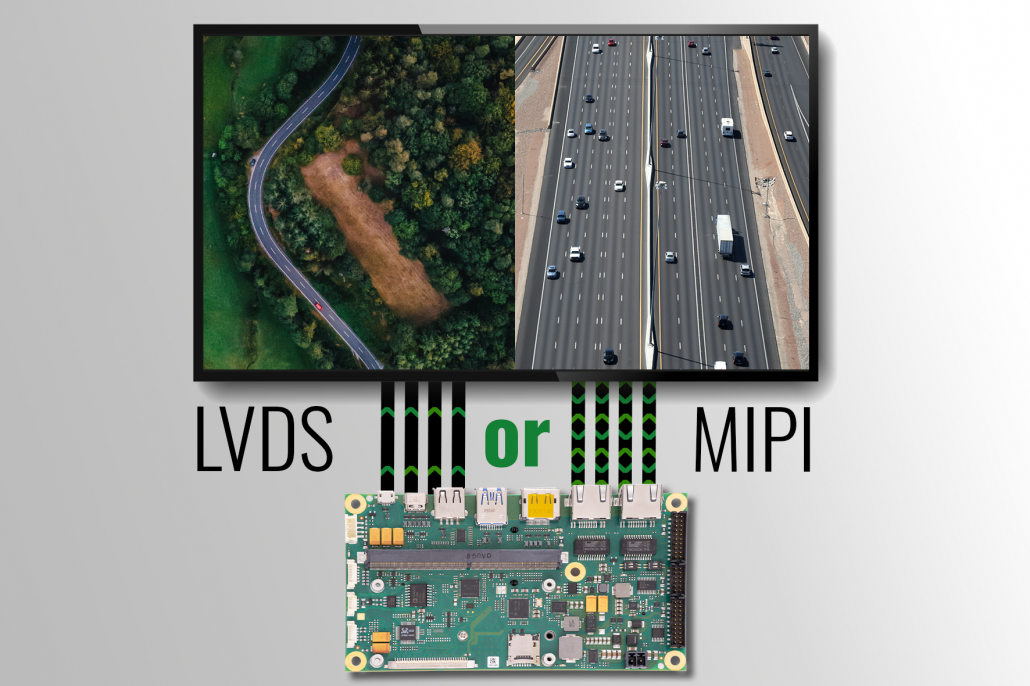

So, we know that both LVDS and MIPI displays follow the LVDS specification and have both differential signaling and twisted wire pairs, which naturally leads to the question: what does set them apart?

The key difference is in the protocol that defined communication over these twisted pairs (as well as some additional wires!). LVDS displays uses the Flat Panel Display Link protocol (FPD-Link), while MIPI displays use the MIPI Display Serial Interface protocol (MIPI DSI), which is a specification of the Mobile Industry Processor Interface (MIPI) Alliance.

When you stop using the acronym, the name is a bit of a giveaway. The MIPI DSI was designed as a cost-effective protocol for the displays in cellphones and other smart devices. So, using a system based on MIPI DSI can, theoretically, reduce the overall cost. But when viewed from a technical perspective, the story can be quite different. A MIPI display has significant layers of added complexity to consider and, overall, this results in a cost not that different to an LVDS display.

For example, MIPI has a TFT cell, it needs drivers, it needs intelligence to “translate” the serial data stream. It needs a backlight and housing. So, when even the components are largely the same, why is it often offered at lower price?

Assuming identical performance, ultimately it comes down to the fact that MIPI displays come from the consumer industry. Consider the sales figures of the world’s most popular smartphones and that will give you an indicator of the kinds of production volumes we are looking at. Vastly higher numbers than compared to, say, products in the industrial or medical world. Logically, higher volumes lead to more competitive component pricing and greater efforts to improve efficiency. So, just through sheer numbers, a high volume MIPI display will usually be cheaper when compared to an LVDS display.

Additionally, as many microprocessors and microcontrollers can drive MIPI displays directly, no display driving board is required to translate the data stream of the processor into the FPD-Link data stream. The intelligence of the application also controls the display directly. This too eliminates components and reduces the overall system price.

However positive and appealing this may see, we do have to address the ‘elephant in the room’. Yes, we benefit from a volume cost saving with MIPI – but this cost saving comes from the same place as MIPI’s key risk: that such displays are aimed at the consumer market. This means that many of the products are not designed with the same longevity in mind as an industrial or medical application (which require many years of support). They are not as sturdy when compared to industrial displays and their integration may be more difficult (e.g., screw-in mounting is not supported). Certainly, we would never advise selecting such a display for use in the medical or industrial world.

This said, they offer excellent benefits for a whole range of product groups – as long as you have a solutions partner who has expertise in ‘driving’ MIPI. Because no two MIPI displays are alike, there are some physical, electrical and communication related adjustment required, and our experts and engineers know them all. Having the right expert at hand who selects you MIPI displays with longevity in mind, who properly considers the levels of robustness required and has the ability to establish proper display driving is essential. And can help you to bring all the benefits of MIPI DSI displays into the prosumer or even the industrial world.

Our display solutions come in a range of form-factors and our display-experts are on hand to guide you in the creation of display or touch solutions that meet your requirements. We can also provide demo units on request.

Find out how Avnet Embedded can propel your product innovation and get in touch today.

Talk to the experts!

Let us know about your product or your challenge and our team will get in touch to discuss how we can help.