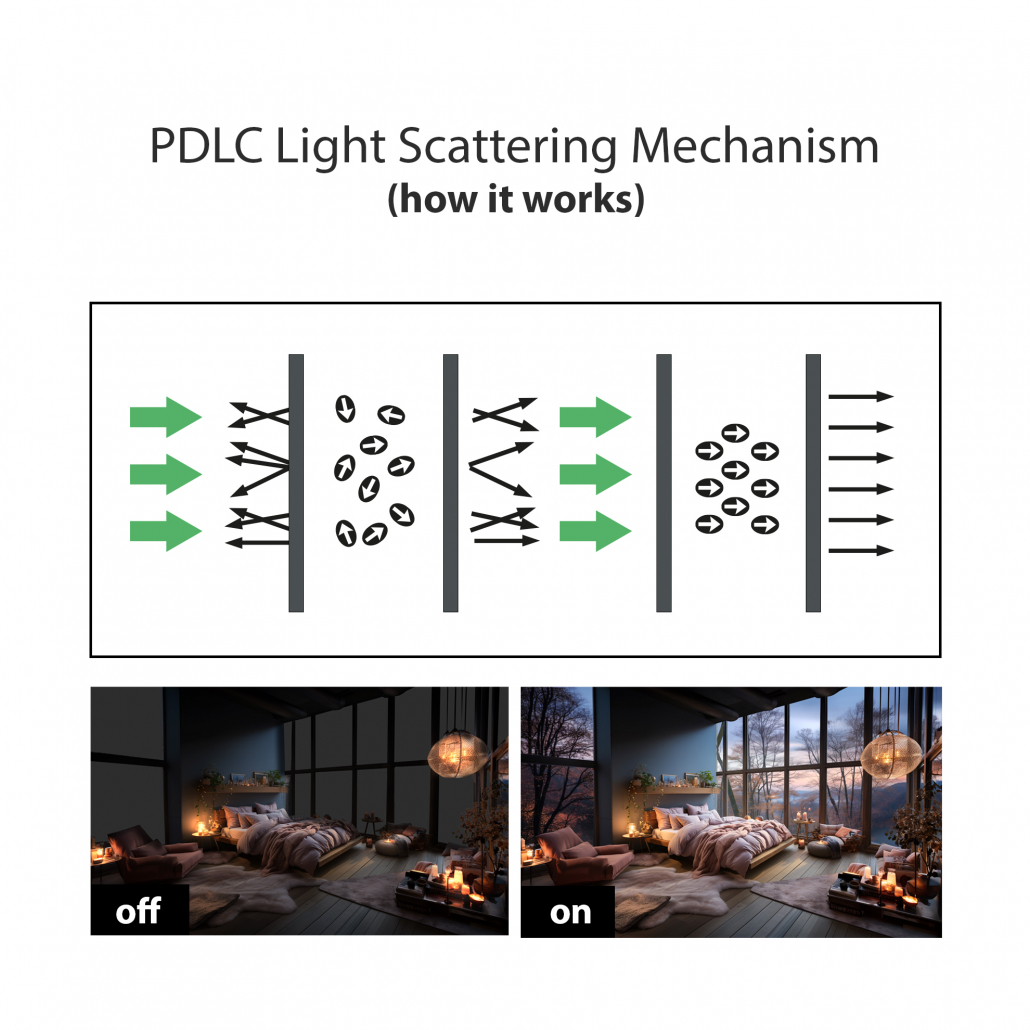

As often happens at Avnet, an acronym is the start of a journey to something pretty cool. Take PDLC, for example. It stands for ‘Polymer Dispersed Liquid Crystals’, which, we must admit, isn’t the catchiest of descriptions. But when you engineer PDLC into glass (or even a self-adhesive film that can be affixed to glass) it becomes much more interesting.

Some people refer to it as ‘smart glass’. We disagree because it doesn’t make glass smart – but it does make it useful. In its essence, it is a photoelectric film that stays transparent only when an AC voltage is applied to it. As soon as the AC voltage is switched off (which you can do easily from a smart home control panel or smartphone app), the film becomes opaque. And, as you can see from the picture, this makes it useful for homes and offices, where it has obvious benefits of privacy and interior design. Particularly in situations where you might wish to make rooms appear larger or smaller to suit circumstances (such as an interior meeting room, for example, or an apartment where space is at a premium).

However, what’s not widely known is that PDLC has other qualities which can serve purposes beyond the aesthetic. For instance, it can offer sound insulation and environmental protection. When PDLC film is embedded in glass it is not only shock resistant but can protect against up to 99% of ultraviolet light.

Which is a nice stat, but what does it mean? In effect, it creates a barrier between a room and external light – which also means heat. So, in hot weather, windows fitted with PDLC can help to reduce the temperature in a room and prevent the fading and ageing of objects inside it. In the age of climate change and smart buildings, PDLC looks certain to play an increasingly important role.

From a display perspective, having the option of turning glass into an opaque surface is pretty handy too. In tandem with a projector, it can offer a cost-effective means of upscaling a meeting space, turning existing glass walls into a simple touch-interface for presentations, which can be easily switched on and off, as required.

Another interesting aspect of PDLC glass is that a touch film can also be applied to it, creating an interactive surface. This moves the technology away from being exclusively used for interiors and very much into a space where it can be claimed for everything from interactive displays, retail kiosks or industrial control panels. Essentially, anywhere you might want to conceal information or controls when they are not in use.

Such combinations of technology always have the potential for interesting and creative applications, which is why we can see beyond the obvious when it comes to PDLC. Our team of display experts at Avnet Embedded are always excited to meet the challenges of our customers and support them in realizing new ways to use existing technologies.

Our experts are on hand to guide you in the creation of display or touch solutions that meet your requirements. Find out how Avnet Embedded can propel your product innovation and get in touch today.

Talk to the experts!

Let us know about your product or your challenge and our team will get in touch to discuss how we can help.