Looks better, feels better, works better: discover the world’s thinnest touch sensor

Today, we’re taking our sensor technology into a new era with the addition of AD Mesh – a lighter, sleeker and more bendable sensor which is a custom build and can be easily adapted customer needs. It joins our existing DITO, SP-ITO and Metal Mesh sensors, which are already widely in use across the world-class displays that we deliver to our customers in every industry.

What makes AD Mesh different?

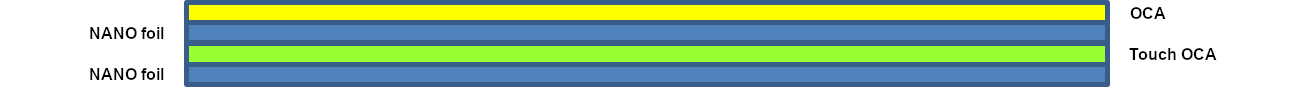

Take a look at the image of a standard Mesh Sensor below. The stack is approximately 04.mm thick, which is pretty light and bendable. As you can see, it’s made from a 2- layer Projective Capacitive touchscreen (PCAP) with optical clear adhesive (OCA) between the X and Y layers. There is also an additional layer of OCA between the Y layer and the cover glass.

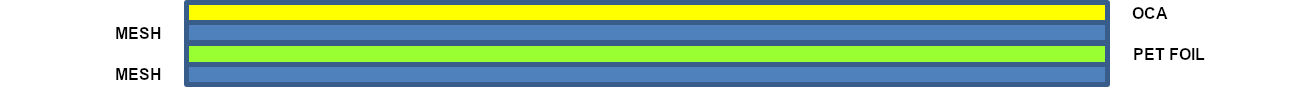

However, the new AD Mesh technology has a substantially thinner stack size, coming in at an astonishing 0.188mm – less than half the size of the standard mesh. This is because there is no OCA between the X and Y layers. Instead, as you can see below, there is a single PET foil.

Now let’s look at a DITO (Dual ITO) sensor. This sensor comprises a glass carrier of 0.55mm thickness (which is standard), along with an ITO X layer on the bottom and ITO Y layer on the top. A layer of glue is also required to bond the DITO Sensor onto the cover glass, which makes it even bulkier still. As you can see, there is a big difference in the thickness of this glass stack.

Looks better, feels better, works better

The minimum achievable resistance of the new AD Mesh is 10-20 ohm/sq, which creates a more responsive and effective touch functionality, even when external parameters (such as noise) may influence the performance of the PCAP. The borders of AD Mesh-based displays are very narrow, with a pitch of only 15um/15um. This means that not only will products using AD Mesh be sleeker, bendable, and lighter but have an improved aesthetic and offer a better user experience. The application opportunities for AD Mesh are particularly exciting, as its potential for customisation means that it can be used where common ITO-based glass sensors may not be able to fit. Size-wise, we can currently offer AD Mesh technology for 21.5” to 65” displays.

Bringing your design to life with AD Mesh has never been easier. We support our customers from end-to-end, from designing the PCAP touch to providing support during system integration. We are highly flexible to custom requirements, such as compact housing, special operability and robustness, and after approval of the solution concept, we can make first samples available within six to eight weeks.

If you’d like to see samples of a complete DTC (Display, Touch, Cover) based on the new AD Mesh technology, please get in touch.